|

|

A

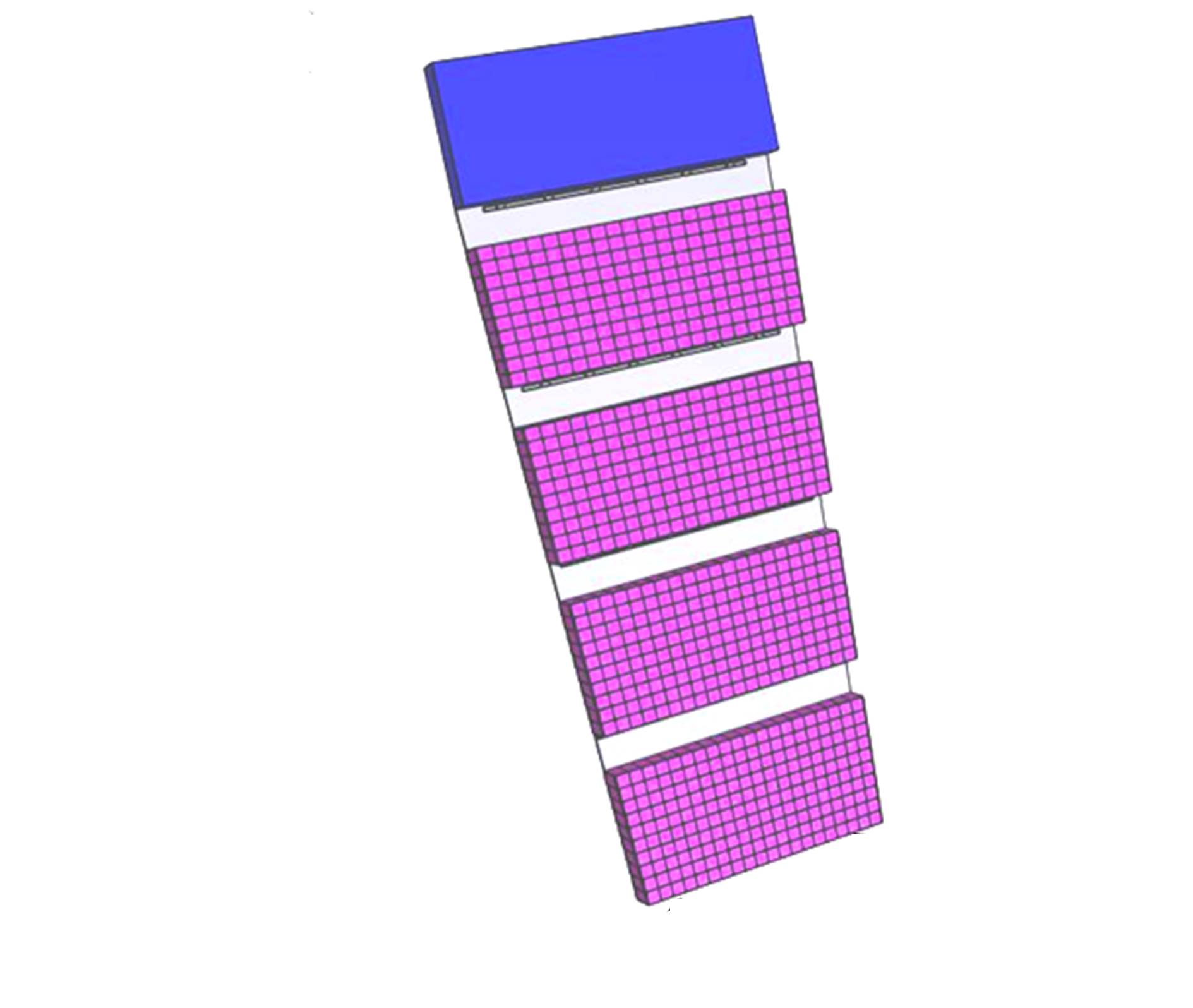

single VIP unit module detector is made of 4 CdTe pixelated detectors

(see Figure 1). CdTe can provide an energy resolution as low as 1.5%

FWHM for a 511 keV incoming particle, which will make the

contribution of scattered events to the final data-set negligible.

Each one of the four detectors has a parallelepiped shape and

consists of ∼ 200 voxels. Each voxel has a size of 1mm x 1mm x 2mm

and is connected to its own independent readout channel for the

energy, position, and arrival time of the gammas. Each readout

channel is bonded to a microchip hosting a fully integrated front-end

electronic as designed and developed by the VIP project.

The

VIP unit detector module is bonded to a thinned read out chip (ROC)

and then mounted on a kapton printed circuit board (PCB). A 2000 V

high voltage is applied with the electric field directed

perpendicular to the surface so that the detector can be run inside a

magnetic field without affecting the signal, for hybrid MRI/PET

operation. The ROC and the PCB are 50 µ m thick each, whereas for

the conductive glue between the ROC, the PCB, and the CdTe detectors

a thickness of 15 µm is assumed. The combined attenuation coefficient

of the passive material accounts for less than 2% compared to 2 mm

CdTe.

The VIP modular design is extremely versatile with the possibility to build virtually any detector geometry by stacking the needed number of modules in arbitrary patterns. The resulting detector has a 3-D segmentation with a channel density of ∼ 470 voxels per cm3.

Figure 1. The basic VIP unit module. It consists of 4 CdTe pixelated detectors of 200 voxels each with trapezoidal shape and a pixel pitch of 1 mm. The smaller base of the first detector is 2 cm, whereas the smaller base of the 4th detector is 2.37 cm. The detector thickness is 2mm.